INP-WealthPk

Azeem Ahmed Khan

Pakistan is set to become one of the world’s leading exporters of salt with the establishment of a state-of-the-art sea salt production facility in Balochistan province.

“This facility, capable of producing 20 million tonnes of the highest quality salt annually, is expected to generate export revenue worth $1.25 billion per year,” Ismail Suttar, Chief Executive Officer of Hub Salt, shared this exciting development with WealthPK.

He revealed that work had already commenced on the project, which spans over 300,000 acres in the proposed areas of Khor Kalmat and Pasni in Balochistan, and requires an investment of $700 million. “The project is currently in the process of reaching financial close,” he added.

He said the project would be completed in phases for six years, thus not requiring the full $700 million investment upfront. “In the initial phase, the facility will produce two million tonnes salt, which will be expanded to four million tonnes per annum within a couple of years.”

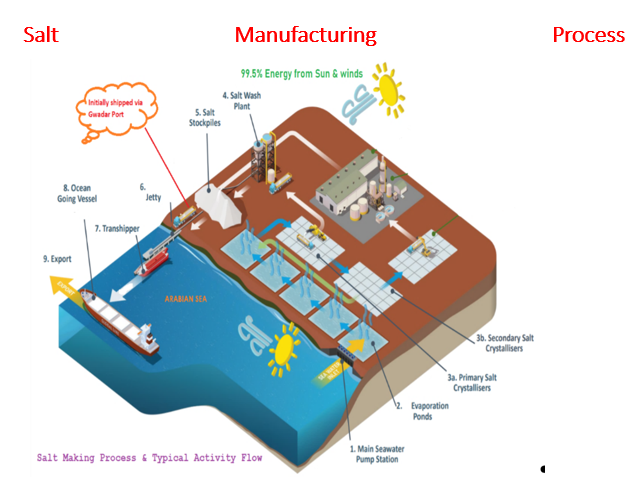

In the early phases, he said it would utilise the Gwadar Port for export. “However, as production increases, a dedicated jetty would be constructed since the current capacity of Gwadar Port is limited to five million tonnes, while the facility aims to handle 20 million tonnes per annum. It will keep expanding to achieve the status of the single largest facility in the world by producing 20 million tonnes salt,” Suttar explained.

He informed WealthPK that the production facility was being implemented through a public-private partnership in cooperation with the Balochistan government. “It will employ indigenous technology, eliminating the need for foreign expertise.” Ismail Suttar expressed confidence that the project would commence operations within one and a half years.

Suttar, who is also the chairman of the Salt Manufacturers Association of Pakistan (SMAP), emphasised that the upcoming Pakistani facility would leverage the latest technology to ensure the production of the finest quality salt worldwide. “The project can attract many salt-consuming industries such as soda ash, chlor-alkali, PVC, leather industry, etc.”

The existing world’s largest salt plant in Mexico was established in 1951, and produces approximately nine million tonnes of salt annually. However, given the advancements in salt production technology since then, it is challenging to incorporate new technology into the outdated facility.

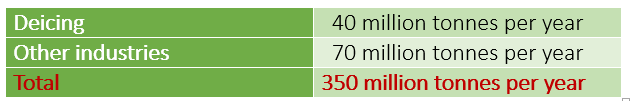

Global salt consumption currently stands at 350 million tonnes annually, with 60% consumed by the chemical industry, 8.6% used by humans and animals, 11.4% used for de-icing of roads and the remaining 20% used as a raw material by other industries.

Suttar said, “The chemical industry is the largest consumer of salt, necessitating the availability of high-quality salt.” Consequently, he added several chemical industries had been established near the Khewra mine in Pakistan to reduce salt transportation costs.

When asked about the need for this huge project, considering Pakistan's abundant salt reserves in Khewra, Suttar explained that while pink salt was beneficial for human health, it contained impurities that made it less suitable for industrial applications.

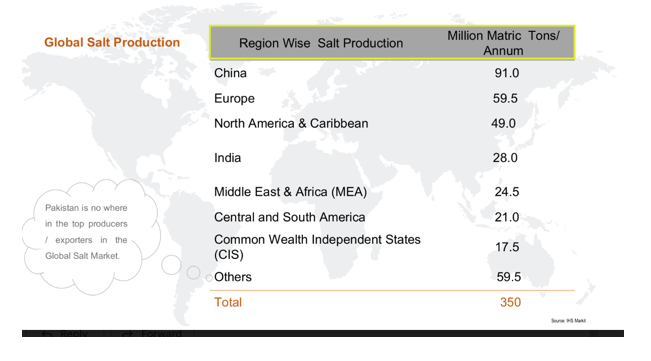

Giving a region-wise breakup of salt production, Ismail Suttar said that at present, China held the position of the world's largest salt producer, followed by Europe, North America and the Caribbean, India, the Middle East, and Africa, Central and South America, and Commonwealth Independent States.

“Although China is the world's largest producer of salt, it is also the largest consumer of salt, and it has to fill in the gap between production and consumption by importing about 20 million tonnes salt annually. The United States is also a net importer, with consumption exceeding production and having to import about 15 to 20 million tonnes annually.”

He maintained that India, which is growing very fast internally in consumption of salt, was unable to add to its production of salt at the pace at which the consumption was growing. “Hence the exportable surplus is diminishing fast, which in a way is good for the Indian economy as it is able to produce its own value-added products by using this cheap mineral, and converting it into valuable chemicals.”

Suttar highlighted that sea salt, or solar salt production through solar evaporation, was the oldest method devised by humans to obtain salt from seawater. “Although this ancient method is still used globally, the upcoming facility in Pakistan will employ the latest technology to ensure efficiency and produce large quantities of salt.”

Explaining the salt manufacturing process, he said seawater was pumped into a series of huge open ponds. “After reaching saturation, salt crystalisation starts in the next set of ponds called crystallisers. Then the salt bed will be harvested, transported, and upgraded into the processing plant for export.”

Presently, Pakistan's sea salt production is limited, with only seven salt works operating solar salt plants in Karachi, producing less than 2,000 tonnes per day. However, salt finds extensive usage across various industries. It is a critical component in pharmaceutical applications such as ORS, intravenous infusions, parenteral solutions, and plasma separations. The textile industry also relies on salt for dye exhaustion and production.

Salt also plays a vital role in water softening, leather processing, soap and detergent manufacturing, skincare products, deodorant, and the production of chlorine and caustic soda. Furthermore, it is widely used for de-icing roads during winter maintenance in several countries.

With Pakistan's ambitious salt production project on the horizon, the country is poised to become a major player in the global salt market. The anticipated export earnings of $1.25 billion annually will contribute significantly to the national economy while showcasing Pakistan's capabilities as a leading salt producer.

Credit: INP-WealthPk