INP-WealthPk

Faiza Tehseen

Indigenous processing and value addition of chalcocite is crucial for Pakistan to enhance the export of its products and strengthen the local industrial and mineral sector, reports WealthPK. Talking to WealthPK, Chief Geologist at Koh-e-Daleel Minerals Company (Pvt) Ltd Abdul Bashir said the local processing of chalcocite will not only increase copper production, revenue generation, and foreign exchange but also bring more job and work opportunities.

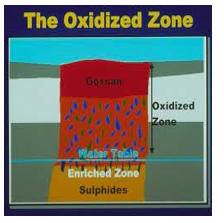

“It will make the country competent in the mineral source market and also act as a stimulant,” he opined. Discussing its occurrence, he said chalcocite was one of the principal ores of copper, a sulfide in nature. The other sulfide ores of copper are pyrite, chalcopyrite, covellite, bornite, etc. They occur in igneous rocks. Chalcocite is of two types — primary and secondary. Primary chalcocite is isolated in its true form as a crystal in igneous rocks, while the secondary chalcocite is formed when it reacts with another sulfide of copper like pyrite, chalcopyrite, bornite, and torbernite. When this sulfuric acid reaction occurs, chalcocite re-forms as a result. Chalcocite is mostly formed in those igneous rock areas where hydrothermal activity takes place. Hydrothermal deposits occur in two types of zones: the hypogene zone and the supergene zone. Chalcocite exists in both the supergene zone and the hypogene zone. The primary chalcocite occurs in the hypogene zone, while the secondary is in the supergene zone. This zone is also called the secondary enrichment zone or chalcocite blanket.

In Pakistan, hydrothermal activity mostly takes place in the igneous belt of Chagai and Northern Areas, including Gilgit and Malakand. The supergene or secondary chalcocite is dominant here caused by the leaching of the already existing sulfide. Leaching takes place when water gets mixed with pyrite or other sulfides of copper and turns into hydrochloric acid, which further reacts with other copper-enriched sulfides like chalcopyrite, bornite, covellite, or the chalcocite itself. The resultant layer of this reaction settles down like a continuous but irregular blanket-like deposit. This is the supergene zone, consisting of high-grade copper ore with a viability of about 79%. The precinct between the secondary zone and the earth’s surface is called the oxide zone or Gossan. Concluding the discussion, Bashir emphasized the positive role of local processing of all minerals including chalcocite.

According to him, it is necessary to form international partnerships that may pave the way for the transfer of modern technology to Pakistan for progressive mining and processing. Chalcocite is used to extract copper and manufacture many industrial products like copper insecticides, copper fungicides, growth stimulants for broiler chickens, supplements to cover copper deficiency in animals, veterinary medicines to stop foot rot, seed dressing, nutrients for rice fields, preservatives for wooden constructions, and scum controllers for farm products, mining, rubber, metal, electrical, leather, construction, chemical and adhesive manufacturing. The copper extracted from chalcocite is useful in jewellery, interior decoration, power generation, transmission, electronic products, wiring, telecommunications, and electronic products. It is high time for Pakistan to get its profit share from the chalcocite market by providing subsidies to import or locally manufacture its processing units.

Credit: INP-WealthPk